cottorindia@cottor.com +91 (22) 2826 4201 / 2 / 3 / 4 / 28346161

Cottor Plants (India) Pvt. Ltd.

Certified ISO 9001 : 2015 Company

36" / 48" New Twin Roll Huller

The Latest Cotton Seed Dehuller is best known for Reliability and Performance. Twin roll hulling has proven to be the highest capacity and most efficient way to hull bulk oil seeds, which include cottonseed, sunflower, soybean, peanuts,

etc.

Cottor has significantly improved on this technology by Offering the most advanced huller on the market today.

The Cotton Seed decorticating / hulling process starts with an adjustable metered roll feeder designed to offer complete consistency and uniformity to the flow rate.

By utilizing an adjustable feed damper and variable speed control, an accurate and reliable feed rate can be maintained.

The heart of the hulling process is the twin, rugged 18" Dia rolls equipped with removable huller knives. These twin rolls are driven at a ratio to enhance the cutting process thus minimizing the amount of uncut and recycle

seed. This ratio combined with a spiral lead on the cutting edges allows the highest percentage of open "hulled" seed available to the separation room. Cotton Seed Dehulling with Cantrell Design Decorticators have proven to bring

minimum Oil Loss in Hulls among all its competitors.

Large Capacity Twin Roll Huller

This Latest Cotton Seed Dehuller is best known for Reliability and Performance and also World’s Highest Capacity Cotton Seed Huller with Twin Drives.

Cottor has significantly improved on this technology by Offering the most

advanced huller on the market today having Highest Capacity per Single Machine.

The Cotton Seed decorticating / hulling process starts with an adjustable metered roll feeder designed to offer complete consistency and uniformity

to the flow rate.

By utilizing an adjustable feed damper and variable speed control, an accurate and reliable feed rate can be maintained.

The heart of the hulling process is the twin, rugged rolls equipped with

24 Nos removable huller knives per Cylinder. These twin rolls are driven at a ratio to enhance the cutting process thus minimizing the amount of uncut and recycle seed. This ratio combined with a spiral lead on the cutting edges

allows the highest percentage of open "hulled" seed available to the separation room. Cotton Seed Dehulling with Cantrell Design Decorticators have proven to bring minimum Oil Loss in Hulls among all its competitors.

Air Density Separator Basket Beater

This new innovative machine is a latest addition to cotton seed processing plant. This is a combination of density separator & five basket fine meat beater separator / scalper for better operational results & low oil loss in hulls.

The hull mixture with fine powder is fed through regulator feeder and in first stage fine powder is separated through spike beater roll moving on basket lined with perforation metal. this fine meat powder is collected through screw

conveyor to oil mill.

Thereafter hull mixture is fed to density separator and uncutseed & heavy meat drops down for recycling process & hulls aspirated from top nozzle to hull beater / hulls godown.

This reliable

& excellent working machine with very few adjustments or control for better working.

60" Beater Separator

The Cottor 60" wide Beater / Shaker is used to produce hulls with a minimum oil content by efficiently beating the hulls to remove the high protein finished meats.

The machine consists of an eight-chamber beater section mounted

above a shaker separator tray. The Beater Separator combines mechanical and pneumatic forces to effectively remove hulls from decorticated oil bearing seeds, including cottonseed, sunflower, soybeans, peanuts, etc.

Solidly

designed and built for most generic hullers to be mounted over the frame. The heart of the hulling process is the twin, rugged 18" dia rolls equipped with removable huller knives. These twin rolls are driven at a ratio to enhance

the cutting process thus minimizing the amount of uncut and recycle seed. This ratio combined with a spiral lead on the cutting edges allows the highest percentage of open "hulled" seed available to the separation room.

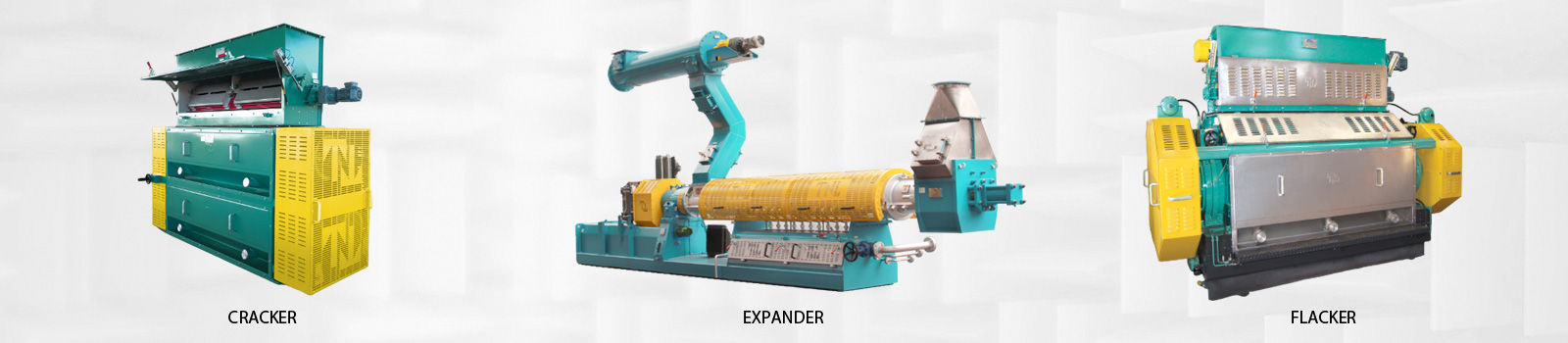

Products

Animated Flow Diagram

Contact Us

Cottor Plants (India) Pvt Ltd,

706, Acme Plaza,

Opposite Sangam Talkies,

Andheri - Kurla Road, Andheri (East),

Mumbai - 400059

Maharashtra, India.

+91 (22) 2826 4201 / 2 / 3 / 4

+91 (22) 2834 6161

cottorindia@cottor.com

All Right Reserved By Cottor Plants (India) Pvt. Ltd.

Designed By Mirackle Solutions